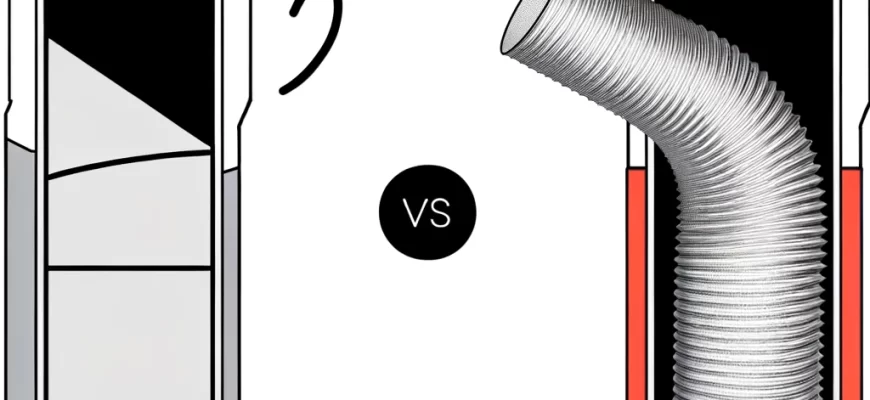

Rigid vs Flexible Chimney Liner

When it comes to ensuring the safety and efficiency of your chimney, selecting the right type of liner is crucial. Chimney liners serve to protect your home from heat transfer and prevent the accumulation of hazardous gases. Among the options available, stainless steel liners stand out for their durability and effectiveness. However, within this category, you must choose between rigid and flexible liners. This article will delve into the differences between rigid and flexible chimney liners, helping you make an informed decision based on your specific needs.

Understanding Rigid Chimney Liners

Rigid chimney liners are made from solid, straight sections of stainless steel and are best suited for chimneys with a straight path without any offsets or significant bends.

Advantages:

Durability: Rigid liners are incredibly durable and resistant to corrosion and heat, making them ideal for wood-burning appliances.

Efficiency: They offer a smooth interior surface that improves airflow and draft, enhancing the efficiency of your heating appliance.

Longevity: With proper maintenance, rigid liners can last for decades, providing a long-term solution for your chimney.

Disadvantages:

Installation Challenges: Rigid liners can be difficult to install in chimneys with bends or offsets. The installation process may require more extensive modifications to the chimney structure.

Cost: Due to their durability and material quality, rigid liners can be more expensive upfront than their flexible counterparts.

Understanding Flexible Chimney Liners

Flexible chimney liners, on the other hand, are made from corrugated stainless steel that can bend and adjust to the contours of your chimney. This flexibility makes them suitable for chimneys with bends, offsets, or irregular shapes.

Advantages:

Versatility: Flexible liners can be maneuvered through complex chimney structures, making them ideal for retrofitting older chimneys that do not have a straight path.

Ease of Installation: The flexibility of these liners significantly simplifies the installation process, often resulting in lower labor costs.

Adaptability: They can accommodate the expansion and contraction caused by temperature changes, reducing the risk of damage over time.

Disadvantages:

Maintenance: The corrugated interior surface can accumulate creosote and soot more easily than the smooth surface of rigid liners, potentially requiring more frequent cleaning.

Durability: While still highly durable, flexible liners may not last as long as rigid liners in certain conditions, especially when used with high-temperature appliances like wood stoves.

Choosing Between Rigid and Flexible Liners

The choice between rigid and flexible chimney liners depends on several factors:

Chimney Structure: If your chimney is straight without any offsets, a rigid liner may be the best option. For chimneys with bends or irregular shapes, a flexible liner will be necessary.

Type of Appliance: Wood-burning appliances that produce high temperatures and corrosive by-products may benefit more from the durability of rigid liners. Flexible liners, however, can be a good choice for gas or oil appliances.

Installation Considerations: If ease of installation and lower initial costs are priorities, flexible liners offer advantages. For those focusing on long-term durability and performance, rigid liners may be preferable.

Conclusion

Both rigid and flexible chimney liners have their place in maintaining the safety and efficiency of your chimney system. Your specific situation—considering your chimney’s architecture, the type of fuel you use, and your budget—will determine the best option for you. Regardless of your choice, ensuring that your chimney liner is correctly installed and regularly maintained is key to protecting your home and ensuring the efficient operation of your heating appliance.